Blog

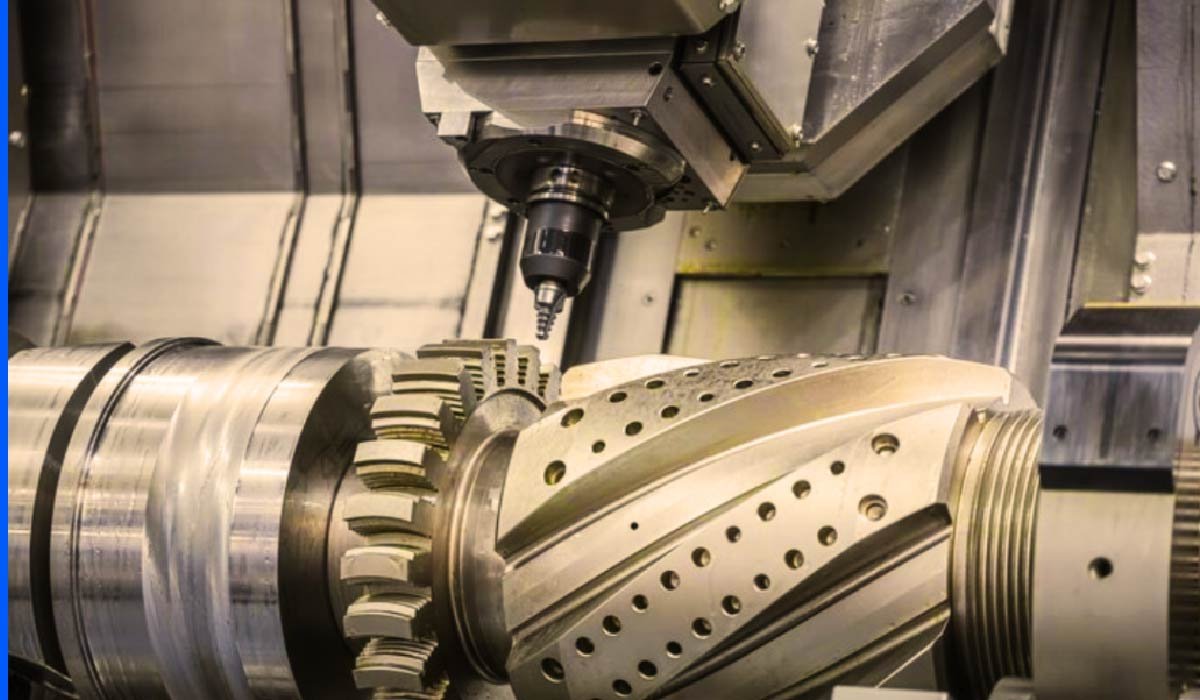

5 Critical Setup Adjustments for Form Taps in CNC Lathes

When you’re using a form tap, you’re not cutting metal. You’re pressing it. That alone changes the game.

Mistakes don’t always show up immediately. Sometimes, the thread looks fine. But it doesn’t hold up under load. Or the tap breaks after just a few parts. That’s why a correct setup is important.

The small things make a big difference. And if you get them wrong, even by a little, you’re going to lose time and tools. That said, we’re going to share with you five critical setup adjustments for form taps in CNC lathes.

Minor diameter sizing for material-specific flow

Here’s the first place most people mess up. They treat pre-drill sizes like they’re fixed. Like there’s one correct size for an M6 x 1.0 thread, and that’s that. But with a form tap, it doesn’t work like that.

Because you’re not cutting, you’re cold-forming. You’re pushing the metal into shape. If the minor diameter is too small, there’s nowhere for the material to flow. That means more torque. More heat. More broken taps.

What’s worse is that each material behaves differently. Soft aluminum needs a different hole than stainless steel. Even within the same material, different lots can behave differently.

Use a chart if you must, but don’t trust it blindly. Use it as a starting point. Then test, measure, and adjust.

Synchronization of feed rate with spindle rotation

A lot of people think “rigid tapping” means the machine just figures it out while it doesn’t.

If your feed per revolution doesn’t match the thread pitch exactly, you’re in trouble. And with form taps, the margin for error is smaller than with cutting taps. Because you’re deforming the material, not slicing it, that makes every little mismatch a problem.

You’ll get twisting, galling, and sometimes the tap just snaps.

Always double-check your feed per rev setting. Don’t just trust the G84 cycle or whatever your control gives you by default. Make sure your spindle encoder is accurate, too. Older machines drift more than you’d think.

Even if you’re using a canned cycle, watch it. Some of them don’t track perfectly at low RPM. If you’re running a small tap in something tough, this matters a lot.

Tap holder float and axial compensation

If you’re using a rigid holder for your form tap, stop.

It might seem more accurate. It might feel like the right choice. But the lack of float is hurting you.

Form tapping builds up pressure quickly. If your tap is even slightly misaligned, you’re going to distort the threads. Or worse, you’ll crack the tap.

Use a floating holder with axial compensation. It lets the tap move just a bit in Z, which reduces the stress. Especially helpful when the machine’s Z-axis doesn’t reverse as precisely as you’d like.

Too much float is no good either. If the holder is sloppy, you’ll get wobble and inconsistent thread depth.

Find that sweet spot. You want a controlled float, not a slope.

Lubrication pressure and delivery focus

Standard flood coolant works fine for some cuts. But not here. The tap is rubbing against metal with a ton of pressure. You need real lubrication at the point of contact. That means directed nozzles. High-pressure delivery. And sometimes, special tap oils or MQL (minimum quantity lubrication).

You’d be surprised how many setups fail just because the coolant stream is hitting the wrong spot. Or because the pressure drops during the cycle. Watch your first few parts. Look at the tap after. Is it dry? Is the lube being pushed away before the tap hits the hole?

Fix the direction. Add a second nozzle. Or switch to a different type of lube that sticks better. If your shop lets you run MQL, try it. The difference in finish and torque is often worth the setup hassle.

Thread depth verification without cutting load

When you’re setting up a new job or running a test part, how are you checking depth? You let the tap run through the cycle, then measure?

That’s a quick way to ruin a good tap before you even get going.

A form tap doesn’t like sudden stops or unexpected friction especiallywhen there’s no lube path worked in yet.

One way around this is to use air tapping on your test pieces. Or manually jog a dull tap through the cycle (without cutting load) to verify Z depth. That lets you confirm the thread goes deep enough without damaging your fresh tool.

Conclusion

Form taps don’t forgive bad setups. Everything needs to line up. Hole size, feed rate, alignment, lubrication, everything. Even how you check thread depth.

Most issues with form tapping don’t come from bad programming. They come from small setup errors that snowball.

For More Information Visit Coopermagazine

-

Celebrity1 year ago

Celebrity1 year agoWho Is Jennifer Rauchet?: All You Need To Know About Pete Hegseth’s Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Mindy Jennings?: All You Need To Know About Ken Jennings Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Enrica Cenzatti?: The Untold Story of Andrea Bocelli’s Ex-Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Klarissa Munz: The Untold Story of Freddie Highmore’s Wife