Blog

Casting: Bronze vs. Aluminum vs. Brass

Metal casting is an ancient yet vital process in modern manufacturing, used to create intricate and complex parts by pouring molten metal into molds. The choice of metal, such as bronze, aluminum, or brass, plays a key role in determining the final product’s strength, appearance, durability, and cost. This guide highlights the differences between these popular non-ferrous alloys to help you choose the best material for your project.

An Overview of Bronze Casting

Bronze, an alloy primarily composed of copper and tin, is one of the oldest materials used in human history. Its discovery marked a significant technological leap, lending its name to the Bronze Age. The casting process for bronze is rich in tradition and remains highly valued for creating durable, artistic, and functional pieces.

Casting Process

Bronze casting typically utilizes methods like investment casting (also known as the lost-wax method), sand casting, and die casting. The lost-wax method is particularly popular for creating detailed art pieces, such as sculptures and plaques. It involves creating a wax model, encasing it in a ceramic shell, melting the wax out, and pouring molten bronze into the resulting cavity.

Advantages of Bronze

- Exceptional Durability: Bronze is known for its strength and resistance to metal fatigue, making it suitable for high-stress applications.

- Corrosion Resistance: It forms a protective patina—a greenish-blue layer—when exposed to the elements. This patina shields the underlying metal from corrosion, contributing to its longevity, especially outdoors.

- Aesthetic Appeal: With its classic, rich reddish-brown hue, bronze has a timeless beauty that is highly sought after for artistic and decorative items.

- Low Metal-on-Metal Friction: This property makes bronze ideal for applications like bushings and bearings where parts slide against each other.

Common Applications

Bronze’s combination of beauty and durability makes it a popular choice for:

- Sculptures and statues

- Architectural elements, such as bronze plaques for buildings and door fittings

- Musical instruments, like cymbals and bells

- Bearings, bushings, and marine hardware

An Overview of Aluminum Casting

Aluminum is a lightweight, silvery-white metal that has become a staple in modern industry since commercial production methods were developed in the late 19th century. Its low density and excellent thermal conductivity make it an attractive choice for a wide range of casting projects.

Casting Process

Aluminum is highly versatile and can be cast using various techniques, including die casting, sand casting, and permanent mold casting. Die casting is particularly common for aluminum due to its low melting point and fluidity, allowing for the rapid production of complex, high-precision parts with smooth surface finishes.

Advantages of Aluminum

- Lightweight: Aluminum is about one-third the weight of steel or bronze, which is a significant advantage in industries like aerospace and automotive where weight reduction is crucial.

- Excellent Corrosion Resistance: Aluminum naturally forms a thin, tough, and transparent oxide layer that protects it from rust and corrosion.

- High Thermal and Electrical Conductivity: It is an excellent conductor of heat and electricity, making it suitable for electrical components and cookware.

- Recyclability: Aluminum can be recycled repeatedly without losing its properties, making it an environmentally friendly option.

Common Applications

Due to its unique properties, aluminum casting is used extensively in:

- Automotive parts, such as engine blocks and wheels

- Aerospace components

- Cookware and kitchen utensils

- Electronic housings and heat sinks

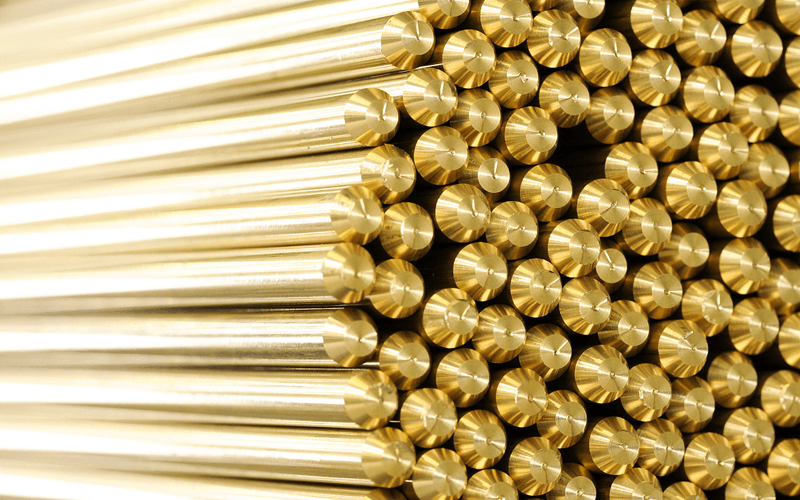

An Overview of Brass Casting

Brass is another copper-based alloy, with zinc being its primary alloying element. Its bright, gold-like appearance, combined with good workability and acoustic properties, has secured its place in both decorative and functional applications.

Casting Process

Like bronze and aluminum, brass can be cast using several methods, including sand casting and die casting. Its relatively low melting point and high fluidity make it easy to work with, allowing for the creation of detailed and intricate designs.

Advantages of Brass

- Aesthetic Versatility: Brass is prized for its attractive, bright yellow finish that resembles gold. It can be polished to a high shine, making it perfect for decorative items.

- Good Corrosion Resistance: While not as resistant as bronze, brass still offers good resistance to corrosion, particularly from water.

- Acoustic Properties: Brass is known for its excellent acoustic qualities, which is why it is the material of choice for many musical instruments.

- Germicidal Properties: The copper content in brass gives it natural antimicrobial properties, making it a hygienic choice for frequently touched surfaces.

Common Applications

The distinct look and functional properties of brass make it ideal for:

- Musical instruments, especially horns and trumpets

- Plumbing fixtures and pipe fittings

- Decorative hardware, such as doorknobs and drawer pulls

- Ammunition casings

Detailed Comparison: Bronze vs. Aluminum vs. Brass

To make an informed decision, it’s helpful to compare these three metals across several key metrics.

| Property | Bronze | Aluminum | Brass |

| Mechanical Properties | High strength, high density, and excellent wear resistance. | Low density (lightweight), moderate strength. | Moderate strength, high malleability, and good ductility. |

| Corrosion Resistance | Excellent. Forms a protective patina that prevents further corrosion. | Excellent. Forms a natural, self-healing oxide layer. | Good, but susceptible to dezincification in high-chlorine environments. |

| Cost | Highest. Copper and tin are relatively expensive metals. | Lowest. Aluminum is abundant and less expensive to produce. | Mid-range. Cost fluctuates with copper and zinc prices. |

| Common Applications | Art, architecture, marine hardware, bearings. | Automotive, aerospace, electronics, cookware. | Musical instruments, plumbing, decorative hardware. |

How to Choose the Right Metal

Your choice between bronze, aluminum, and brass should be guided by the specific needs of your project. Here are some final considerations:

- For Strength and Longevity: If your project requires maximum durability and the ability to withstand harsh environmental conditions, bronze is an unparalleled choice. Its resilience makes it perfect for outdoor monuments and heavy-duty industrial parts.

- For Lightweight and Modern Applications: When weight is a primary concern, such as in the automotive or aerospace industries, aluminum is the clear winner. Its combination of low density and good strength offers significant performance advantages.

- For Decorative Appeal and Acoustics: If aesthetics are paramount and you desire a brilliant, gold-like finish, brass is an excellent option. It is also the go-to material for musical instruments due to its unique acoustic properties.

By carefully weighing the mechanical properties, corrosion resistance, cost, and intended application, you can confidently select the metal that will bring your vision to life with the best possible results.

Conclusion

Now that we have explored the properties, characteristics, and applications of brass, it is clear that this versatile alloy offers many benefits for various industries. Its unique combination of strength, ductility, corrosion resistance, and aesthetics make it an ideal choice for a wide range of applications.

-

Celebrity11 months ago

Celebrity11 months agoWho Is Jennifer Rauchet?: All You Need To Know About Pete Hegseth’s Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Mallory Plotnik?: The Untold Story of Phil Wickham’s Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Klarissa Munz: The Untold Story of Freddie Highmore’s Wife

-

Celebrity1 year ago

Celebrity1 year agoMeet Christina Erika Carandini Lee?: All You Need To Know Christopher Lee’s Daughter