Technology

How to Keep Balcony & RV Solar Working in Shade in 2025

Solar should be simple: point panels at the sky and harvest clean power. Reality—trees, railings, roof racks, hail, heat, and constant vibration—gets in the way. Here’s a clear, non-hype look at a hardware approach that keeps energy flowing when conditions aren’t textbook.

The everyday problem solar rarely talks about: partial shade

A single sliver of shade can drag an entire panel—or even a whole string—down. That’s because a shaded cell turns into a bottleneck: resistance rises, current stalls, and local hotspots can develop. Beyond lost kilowatt-hours, hotspots shorten module life and raise maintenance risk, especially on sites with moving shadows (chimneys, trees, balcony railings, antennas, bike racks on RV roofs).

Bottom line: If your install will ever see partial shade, you need more than “good irradiance.” You need panels that tolerate it gracefully.

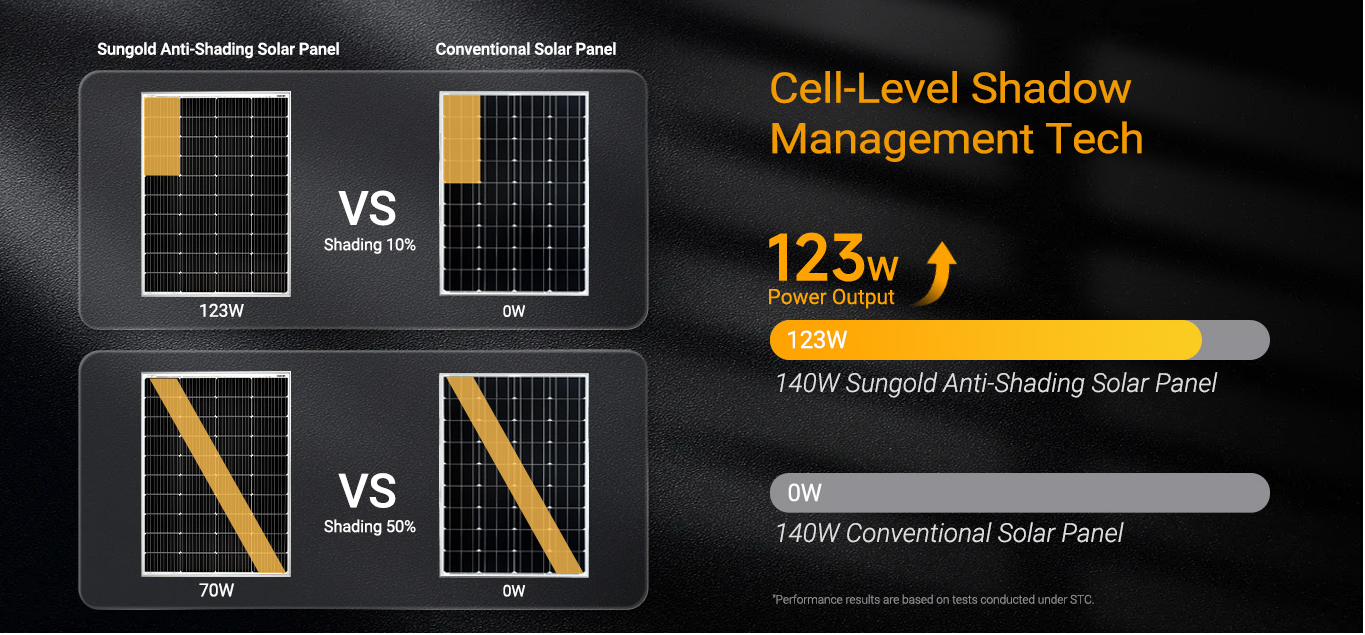

A quick explainer: cell-level shadow management

Sungold’s cell-level shadow management builds smart current-routing paths into the laminate so electricity can flow around shaded cells rather than through them. When resistance spikes in a shaded cell, these paths automatically redirect current, which helps avoid hotspots and keeps useful power coming out of the module. In simple English: the sunny parts keep working while the shaded parts sit out.

On manufacturer tests, this architecture maintains output under partial shade patterns where conventional layouts would sag dramatically—think “50% shaded, ~50% output” as a design target, not a worst-case collapse.

PA621: built for motion, weight limits, and the elements

If shadow management is the brain, Sungold PA621 is the body designed for real-world installs:

Truly lightweight (≈2–3 kg per panel): Easy to lift and mount on RV roofs and balcony railings without structural reinforcement—a meaningful safety and labor win for urban sites.

Anti-vibration construction (10–60 Hz): Keeps its integrity on the move—relevant for vans, cold-chain trucks, and boats where road shock causes early failures on standard glass modules.

Reinforced composite backsheet (non-glass): Disperses impact energy from bumps and drops, protecting cells against micro-cracks.

Slow heat transfer: The composite stack reduces rapid heat soak into roofs/cabins, helping moderate temperature spikes on summer days.

Weather durability: Tested for UV/moisture resistance with limited yellowing (Δb ≤ 3 after 2,000 h DH85) and minimal power loss after hail impact (~0.12%).

Aesthetically, the module’s all-black look is unobtrusive on visible facades—useful when planning permission or neighbor acceptance matters on UK terraces and balconies.

Where this shines

1) Urban balconies and terraces (UK & EU cities)

Challenge: Strict weight limits, tight space, and railings that throw mid-day bars of shade.

What helps: A 2–3 kg, thin laminate installs with lighter hardware, and cell-level rerouting keeps wattage steady as the sun moves. Surface durability resists pollution and weathering over the seasons.

2) RVs, campervans, and expedition rigs

Challenge: Antennas, roof racks, trees at campsites, and constant vibration—exactly the conditions glass modules dislike.

What helps: Anti-vibration design (10–60 Hz), impact-tolerant laminate, and shade-resilient circuitry—so the sunny half of the panel still delivers when a branch clips the other half.

3) Cold-chain and mobile retail vehicles

Challenge: Curved roofs, HVAC shadows, height constraints, and long-distance road shock.

What helps: Flexible, light construction reduces structural strain; cell-level shadow management stabilizes output around vents and rails; slower heat transfer eases rooftop thermal stress.

How the tech translates to performance (without the jargon)

Keeps energy flowing in patchy light: Smart paths steer current around shaded zones, so your inverter/MPPT still sees workable power instead of a brownout.

Avoids the “hotspot cascade”: Less localized overheating means fewer laminate scars and a lower chance of early failures.

Protects your mounting surface: Lightweight panels reduce roof loads, and slower heat transfer can help moderate the “hot roof” effect.

Designed for the long haul: Lab and impact tests indicate minimal yellowing and tiny post-hail power loss, supporting stable appearance and output over time.

Buying checklist (engineers and DIYers alike)

Map your shadows. Look for railings, chimneys, masts, racks, and nearby trees. If any appear, prioritize cell-level shadow management rather than standard stringing.

Check roof/railing limits. If you have weight caps or can’t add heavy sub-frames, a 2–3 kg class panel changes what’s feasible—especially on flats and terraces.

Match the electronics. A good MPPT (or microinverters on balconies) helps harvest the panel’s shade resilience; don’t pair innovative hardware with bargain-basement power electronics.

Think vibration & impact. For vehicles and boats, anti-vibration design and non-glass laminates are about reliability, not spec-sheet flair.

Ask for durability data. UV/moisture aging (e.g., Δb after DH85 exposure) and hail-impact results say more than generic “weather resistant” claims.

Plan cable runs early. Keep leads tidy, strain-relieved, and away from pinch points; shade-savvy panels still need shade-savvy wiring.

Real-world scenarios (and why they work)

Balcony railings: Morning and afternoon bars of shade sweep across the module. PA621’s cell-level routing lets the lit regions keep producing useful watts instead of letting the shadowed cells choke the whole panel.

Under trees at a campsite: Dappled shade constantly moves with wind. Instead of full-string dropouts, you get “graceful degradation”—the panel scales down proportionally to the shaded area.

City grime + weather cycles: The laminate stack is built for UV and moisture; tests show limited yellowing and sustained appearance, which matters for visible installs.

The business angle: fewer surprises, better uptime

For installers and small energy brands, the economics of shade-resilient, lightweight panels show up in places spreadsheets often miss:

Simpler mounting: Less steel and fewer roof penetrations on terraces/vehicles.

Fewer callbacks: Hotspot suppression and impact tolerance reduce early failures and warranty pain.

More predictable yield: Proportional output in partial shade = fewer “client is under-generating” emails.

Faster deployment: Two-kilogram class modules are easier to haul up stairwells and onto van roofs.

FAQ

Does this replace good siting?

No. Always minimize shade where possible. Shadow-resilient panels are about graceful handling of the shade you can’t avoid.

Is it only for flexible roofs?

No. The reinforced non-glass construction works on flat or curved surfaces, but vehicle use benefits most from the anti-vibration stack.

What about hail and long-term looks?

Manufacturer tests show ~0.12% power loss after hail impact and limited yellowing after 2,000 h DH85—useful signals for longevity. Ask for the test summaries when you spec.

-

Celebrity1 year ago

Celebrity1 year agoWho Is Jennifer Rauchet?: All You Need To Know About Pete Hegseth’s Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Mindy Jennings?: All You Need To Know About Ken Jennings Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Enrica Cenzatti?: The Untold Story of Andrea Bocelli’s Ex-Wife

-

Celebrity2 years ago

Celebrity2 years agoWho Is Klarissa Munz: The Untold Story of Freddie Highmore’s Wife