Business

The Role of CNC Machines in Today’s Manufacturing World

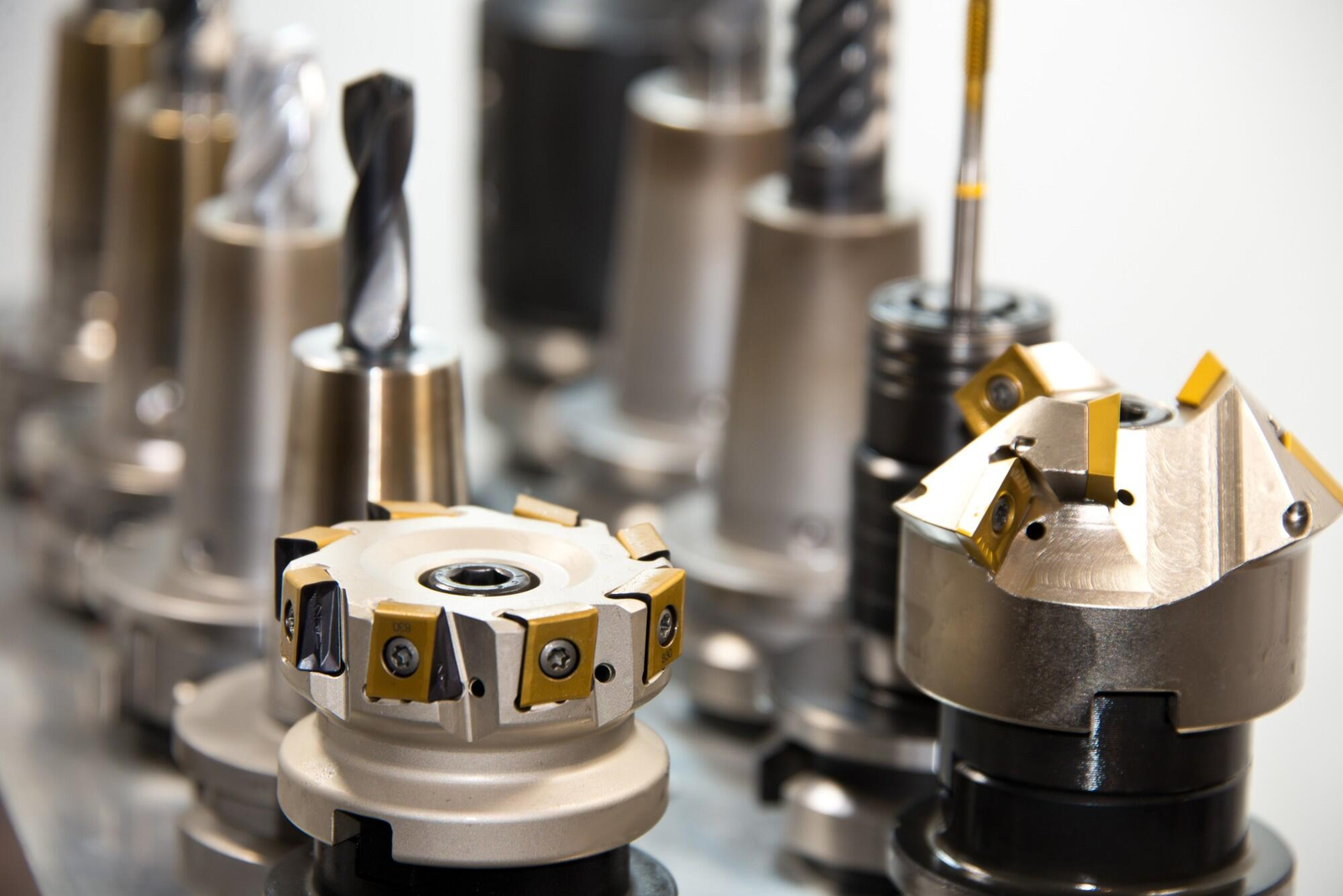

Manufacturing today depends on accuracy, speed, and consistency. Traditional methods struggle to keep up with modern demands. That’s why CNC machines have taken over many production floors.

These systems use computer control to shape and cut materials. They reduce human error and keep outputs consistent across batches. They also help companies work faster and lower production costs.

If you’re exploring smarter ways to produce, it’s worth looking into the power of CNC machines. Explore the sections below to see how CNC machines are reshaping the manufacturing world.

Improving Accuracy in Production

CNC machines follow detailed digital instructions, which means fewer mistakes in every batch. This level of precision is hard to match with manual tools. In industries where tight tolerances matter, CNC systems keep things on track.

Each part comes out the same, time after time. This is key in sectors like aerospace, electronics, and automotive. As a result, manufacturers can avoid waste and rework.

Speeding Up Manufacturing Processes

CNC machines run continuously with minimal downtime. Once the program is set, production moves fast. This allows companies to meet tight deadlines without cutting corners.

Workers can focus on other tasks while machines operate. Output levels stay high, even with complex designs. It’s a faster way to keep up with demand.

Lowering Long-Term Costs

The upfront cost of CNC machines can be high, but the savings add up. Less scrap, fewer errors, and lower labor costs make a difference. Since they need less supervision, companies save on wages.

Machine wear is lower thanks to steady operation and fewer tool changes. Over time, the return on investment becomes clear. This makes CNC a smart move for growing operations.

Supporting Custom and Complex Designs

CNC systems are ideal for parts that are hard to make by hand. Their computer-driven movements allow for shapes and cuts that would be difficult manually. This makes them useful in industries with changing needs and one-off builds.

Programs can be adjusted without slowing down production. Thanks to this, more businesses now offer custom services. Many rely on precision CNC turning and milling services to meet these unique requirements.

Boosting Workforce Efficiency

With CNC machines in place, teams can do more with less. Workers don’t need to monitor every step, just ensure proper setup and maintenance. This shifts labor to higher-value tasks like quality checks and planning.

It also reduces injury risks from repetitive tool handling. Training on CNC use is often quicker than learning traditional methods. That helps onboard new team members faster.

Enhancing Product Quality

Since CNC machines follow exact instructions, each product stays true to the design. There’s little room for variation once the program runs. Better quality builds customer trust and lowers return rates.

It also means fewer inspections and adjustments. Companies can guarantee a higher level of consistency. This edge helps them stay competitive in tight markets.

CNC Machines Are Important in Today’s Manufacturing World

CNC machines have become essential in modern manufacturing. They bring speed, accuracy, and flexibility to the production floor. These machines help lower costs while improving the end result.

Businesses looking to scale or stay ahead should consider integrating CNC processes. It’s one of the smartest ways to improve output and quality in today’s fast-paced world.

For more topics, visit our blog!

-

Celebrity1 year ago

Celebrity1 year agoWho Is Jennifer Rauchet?: All You Need To Know About Pete Hegseth’s Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Mindy Jennings?: All You Need To Know About Ken Jennings Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Enrica Cenzatti?: The Untold Story of Andrea Bocelli’s Ex-Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Klarissa Munz: The Untold Story of Freddie Highmore’s Wife