Business

Expert Metal Fabrication in Perth: Crafting Precision and Quality

In the industrial sector, precision and quality in manufacturing processes are paramount. This is particularly true for metal fabrication in Perth. The region is home to numerous fabrication facilities providing top-tier services that cater to varying industrial needs. Companies like Kanyana Engineering Pty Ltd are leading the charge, ensuring that their outputs meet the highest standards of excellence.

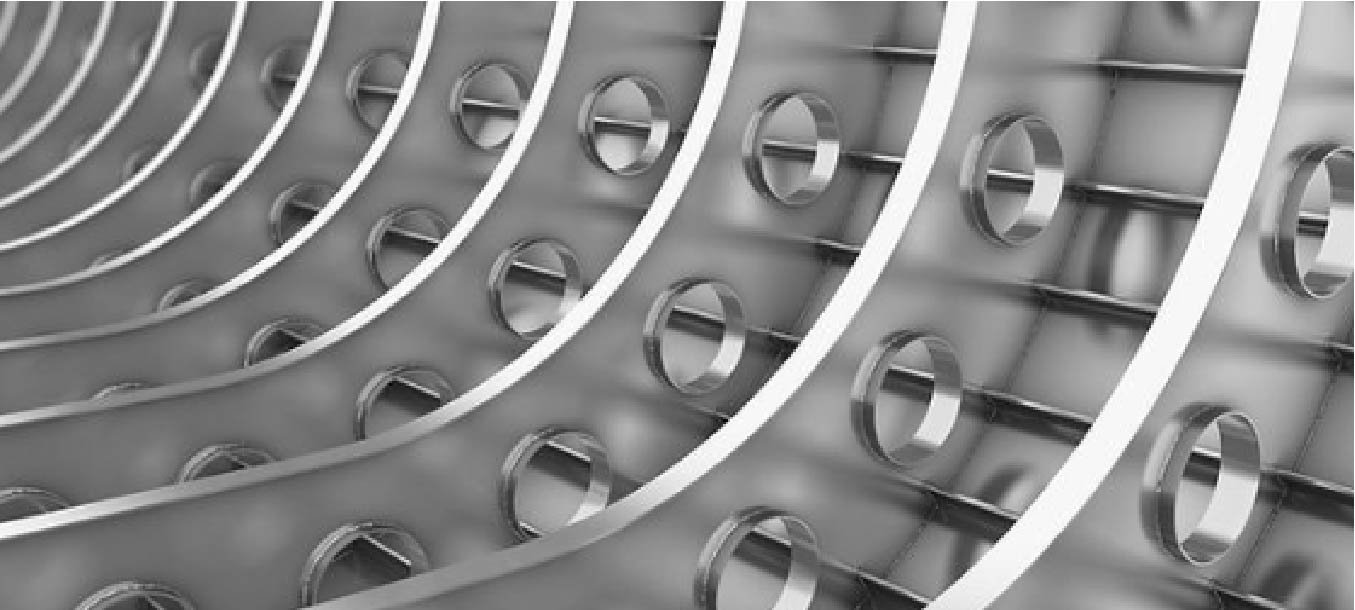

Metal fabrication involves the creation of metal structures through cutting, bending, and assembling processes. It is a method that requires adept skill and technological assistance to produce components used across different industries. Consumers of metal fabrication products span sectors such as construction, automotive, and aeronautical, each requiring bespoke solutions that meet rigorous specifications.

The Importance of Expertise in Metal Fabrication

Expertise in metal fabrication is essential due to the complex nature of the tasks involved. Skilled engineers and fabricators must work in tandem to interpret designs, understand materials science, and operate advanced machinery. This collaboration ensures that the final products not only fit their intended purpose but also adhere to safety and durability standards.

Facilities offering metal fabrication in Perth are equipped with state-of-the-art tools and machinery. These include laser cutters, CNC machines, and welding stations, enabling precise cuts and joins. With the use of such technology, fabrication companies can produce components that range from minute pieces with tight tolerances to larger, robust structures.

Processes Involved in Metal Fabrication

Metal fabrication is an intricate process that consists of three primary stages: cutting, forming, and assembly. Each stage plays a crucial role in transforming raw material into finished products.

Cutting

Cutting is the initial stage in metal fabrication, involving dividing the raw material into the required shapes and sizes. This process often employs technologies such as laser cutting, plasma cutting, and water jet cutting, each offering varying levels of precision depending on the material and complexity involved.

Forming

Forming refers to the process of bending or pressing metals into desired forms. Techniques such as rolling, bending, and stamping are utilised to reshape metal sheets without altering their volume. This stage is critical for creating parts with specified angles and curves.

Assembly

The assembly process involves connecting different metal pieces into a single structure. Welding, fastening, and riveting are common methods used to join metal components. The quality of the assembly process is vital as it affects the structural integrity and functionality of the final product.

Quality Assurance in Metal Fabrication

Quality assurance is an integral part of metal fabrication services. Companies must ensure that their outputs meet both regulatory standards and client expectations. This is achieved through rigorous testing and inspection phases throughout the production process.

Non-destructive testing methods, such as X-ray and ultrasonic testing, are employed to detect any defects within welded joints or metal structures. These methods help in identifying potential weaknesses that could compromise the safety and longevity of the product.

Why Choose Perth for Metal Fabrication?

Perth is strategically located to offer a unique advantage when it comes to metal fabrication services. The city’s proximity to major mining operations and shipping routes makes it an ideal hub for industrial activities, including fabrication. This accessibility ensures that materials and finished goods can be efficiently transported, reducing both time and costs associated with logistics.

Additionally, the pool of skilled fabricators and engineers in Perth is another factor that enhances the quality of services offered. Education and training facilities in the region provide a continuous influx of qualified professionals into the industry, fostering innovation and maintaining high standards in metal fabrication.

Environmental Considerations in Metal Fabrication

Modern metal fabrication processes in Perth adhere to sustainable practices to minimise environmental impact. Fabrication companies are increasingly adopting recycling initiatives to manage waste effectively. Using recycled materials not only reduces waste but also decreases the overall energy consumption of the manufacturing process.

Moreover, efficient energy management systems are being implemented in facilities to further reduce carbon footprints. These practices underscore a commitment to sustainability and innovation within the industry.

In conclusion, metal fabrication in Perth continuously evolves with advancements in technology and industry practices. Companies like Kanyana Engineering Pty Ltd are at the forefront, offering refined skills and unparalleled expertise in crafting precision and quality products. Their commitment to delivering exceptional results makes Perth a vital player in the metal fabrication industry.

-

Celebrity1 year ago

Celebrity1 year agoWho Is Jennifer Rauchet?: All You Need To Know About Pete Hegseth’s Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Mindy Jennings?: All You Need To Know About Ken Jennings Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Enrica Cenzatti?: The Untold Story of Andrea Bocelli’s Ex-Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Klarissa Munz: The Untold Story of Freddie Highmore’s Wife