Blog

What is Torque Calibration?

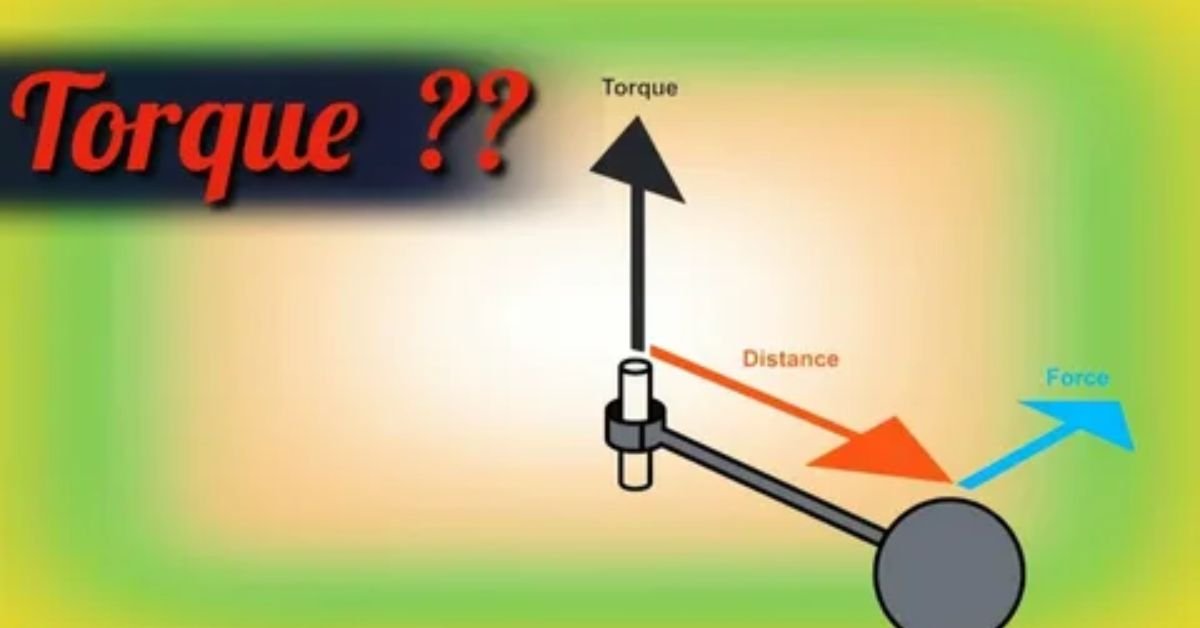

Torque calibration is the process of checking and adjusting tools like torque wrenches to make sure they apply the right amount of force. Torque is the twisting force that tightens bolts or screws. When a tool is calibrated it is tested against a standard to ensure accuracy. This keeps things safe and precise in many industries.

Imagine a mechanic tightening a car wheel’s bolts too loosely or too tightly. A loose bolt could make the wheel fall off while driving. A too-tight bolt might break or damage the car. Torque calibration prevents these dangers by ensuring tools work perfectly every time.

This article will dive into why torque calibration matters and how it is done. You will learn about its role in fields like automotive and aerospace. We will also cover the benefits and simple tips for keeping tools in top shape. Stick around to understand this key process in a clear fun way.

Understanding Torque Calibration

Torque calibration is all about making sure tools like torque wrenches give the right amount of twisting force. It involves testing these tools against a known standard to check their accuracy. When a tool is calibrated it tightens bolts or screws just right. This process is super important for keeping things safe and reliable.

Think of a bike wheel that needs its bolts tightened perfectly. If the bolts are too loose the wheel might wobble or come off. If they are too tight the bike could get damaged. Torque calibration ensures every bolt is spot on with tools from Crane Electronics saving the day in places like car shops or factories.

Why Torque Calibration Matters

Calibration keeps tools accurate which is crucial in industries like cars or airplanes. Accurate tools mean safer vehicles and machines that last longer. It also helps meet strict rules set by experts for quality work.

How It Is Done

A technician uses special equipment to test a torque tool’s force. The tool is compared to a super precise standard to see if it is correct. If it is off the tool gets adjusted to be perfect again.

The Torque Calibration Process

Torque calibration is the method of testing tools to ensure they apply the right twisting force. A technician checks tools like torque wrenches using special machines from Crane Electronics. These machines compare the tool’s force to a known standard. If the tool is off it gets fixed to be accurate.

Picture a car factory where every bolt needs perfect tightening. Without calibration a loose bolt could cause a breakdown or a too tight bolt might crack parts. The calibration process catches these issues before they happen. It keeps tools spot on for safe and quality work.

Here are key points about the torque calibration process:

- Tools are tested with devices like torque testers for accuracy.

- Calibration happens regularly based on how often the tool is used.

- Professionals in labs or workshops usually handle the process.

- The goal is to match the tool’s force to an exact standard.

- Proper calibration prevents costly mistakes in industries like automotive or construction.

Who Performs Torque Calibration

Skilled technicians or certified labs carry out torque calibration. They use advanced equipment to test and adjust tools. Their expertise ensures every tool meets strict standards. This keeps industries running smoothly and safely.

How Often Should Tools Be Calibrated

Calibration frequency depends on how much a tool is used. Heavy use means more frequent checks often every few months. Light use might need calibration once a year. Regular checks keep tools reliable and prevent errors.

Applications and Benefits

Torque calibration is used in many industries to keep tools accurate. From car repair shops to airplane factories it ensures bolts are tightened just right. This process helps build safe and strong products like vehicles or bridges. It is a key step for quality and precision everywhere.

Imagine a wind turbine spinning smoothly because its bolts are perfectly tightened. Torque calibration makes this possible by preventing loose or overly tight parts. It saves money by avoiding repairs and keeps workers safe. The benefits touch everything from daily cars to massive machines.

Where Torque Calibration Shines

Torque calibration is vital in fields like automotive aerospace and construction. It ensures car engines are assembled correctly and airplane parts stay secure. Even energy sectors rely on it for safe wind turbines. This process supports strong reliable builds across industries.

Why Calibration Saves the Day

Regular calibration boosts safety by preventing bolt failures. It makes equipment last longer and work better. It also helps companies follow strict quality rules. Calibrated tools mean fewer mistakes and happier customers.

Conclusion

Torque calibration might sound technical but it is a game changer for safety and quality. It ensures tools tighten bolts perfectly keeping cars planes and buildings strong. By making calibration a priority industries avoid costly errors and keep things running smoothly. This process is the unsung hero behind reliable machines we use every day.

Whether you are a mechanic or just curious about how things work torque calibration matters. It protects lives saves money and keeps standards high. Next time you drive a car or fly in a plane thank calibration for the secure bolts. Explore more about it or share this knowledge with your mates.

FAQs

What does torque calibration do?

It checks tools like torque wrenches to make sure they apply the right force. This keeps bolts tightened correctly for safety and quality.

How often should I calibrate my tools?

It depends on use. Heavy daily use might need checks every few months while light use can go a year.

Can I calibrate my own torque wrench?

It is possible but tricky. Pros with special equipment do it best to ensure accuracy.

Why is calibration important for safety?

It prevents loose or overly tight bolts which can cause accidents or breakdowns in cars or machines.

Which industries need torque calibration?

Car repair airplane building construction and energy sectors all rely on it for strong safe products.

-

Celebrity1 year ago

Celebrity1 year agoWho Is Jennifer Rauchet?: All You Need To Know About Pete Hegseth’s Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Mindy Jennings?: All You Need To Know About Ken Jennings Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Enrica Cenzatti?: The Untold Story of Andrea Bocelli’s Ex-Wife

-

Celebrity1 year ago

Celebrity1 year agoWho Is Klarissa Munz: The Untold Story of Freddie Highmore’s Wife